What is Manufactured Stone Veneer

Manufactured stone veneer is a generic term and is often referred to using many different names for example:

Reconstituted stone, Faux stone, Engineered stone, Cultured stone – the list goes on.

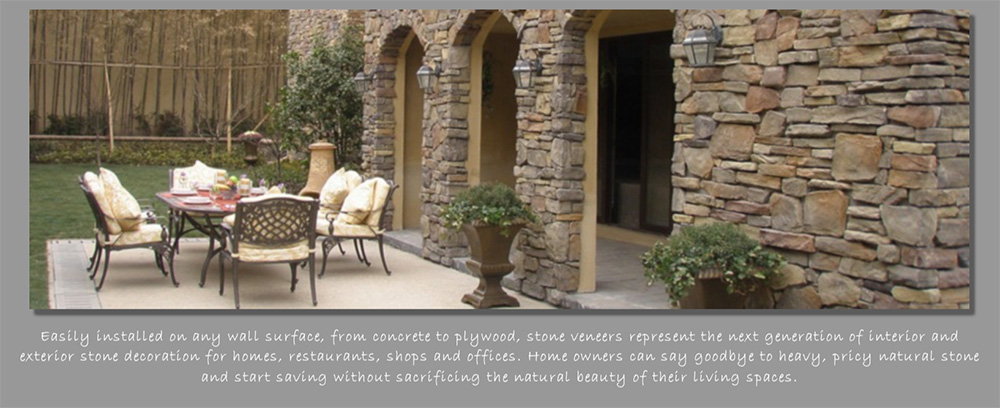

Manufactured stone veneer can be used for interior and exterior non-structural uses. This man-made stone is a lightweight veneer facing that can be applied to a variety of surfaces including masonry, metal-framed or wood-framed construction providing a variety of architectural aesthetics.

Manufactured stone is handcrafted from moulds using individually selected stones that create elegant replicas of the real thing.

Stone veneer is cast from a mix of Portland cement, lightweight natural aggregates, proprietary additives and carefully selected iron oxide pigments. The permanent mineral oxide pigments become an integral part of the product and are fade resistant, with only minimal colour changes after years of weathering — similar to natural stone. Additional colour pigments are applied, often by hand, creating marbled, multi-shade accent colours that add to the authentic look.

When stripped from the moulds, you have a veneer that looks, feels and lasts like natural stone, but lighter in weight and thus, easier to install.

By utilizing natural materials in a lightweight concrete design, the products can adhere to a variety of sound substrates, indoors and outdoors, and will withstand the test of time in even the harshest environments.

By embracing the very best of modern cement and mould making technologies, Brikstone are able to offer a range of veneers that are typically between 10 – 15mm thick. This ensures that the customer is firstly only paying for an absolute minimum amount of raw materials and secondly this reduces the handling costs and preparation costs required to make the substrate suitable for installation.

The popularity of engineered stone cladding has meant that an increasing number of homeowners are using it to reface their run-down fireplaces, finish entertainment areas, basements, wine cellars, archways, kitchen backsplashes, kitchen islands, and even staircases or stairwells.

Inspired by nature, manufactured Stone is modelled on natural stone, and in comparison, has very little impact on our natural resources and the environment. Durable, light weight, and easy to work with, these products provide a cost effective and practical way to enhance interiors, bringing the rustic warmth of the outside to the inside, including bathrooms, living rooms, kitchens, fireplaces and many more applications. Using manufactured stone instead of natural stone leads to remarkable savings. Besides the lower cost of the product itself, manufactured stone veneer’s light weight means a substantial reduction in the cost of shipping, labour, and foundations and footings.

Unlike natural stone, one is not limited to natural stone resources or availability. A wide variety of designs and colours are quite easily manufactured – at a fraction of the cost.

Because of their many advantages, manufactured stone has become a popular choice for home decoration. Firstly, manufactured stone presents a less costly option and secondly, it offers versatility and can be applied almost anywhere with ease. Manufactured Stone is becoming an increasingly popular choice with home owners and architects to create a distinct and novel appeal to the interiors and exteriors of homes and commercial buildings.

Builders and home renovators usually apply engineered stones to cover old and boring exterior bricks as well as cracking and discoloured render. In fact, modern house designs often incorporate stone veneers to make an architectural statement by covering the entire stone facade or a selection of interior feature walls with carefully man-made stone accents. Engineered stone is the ideal cladding material for any creative designer given its lightweight and maintenance-free composition.

Stone veneers are an attractive and increasingly popular way to decorate a property, but they’re more than that. Stone veneers are also an extremely cost-effective alternative that saves builders and buyers money in a time when every penny counts.